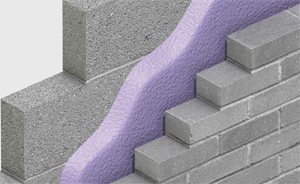

Polythermal Masonry Insulation

Description:

Polythermal is used to restore the structural stability and reduce the thermal transmittance of existing cavity walls, with masonry inner and outer levels, in which the conventional wall ties have corroded. It is also used in new construction where its superior thermal performance and resistance to flood water is of importance. It has excellent resistance to driving rain and can be installed in all geographical exposure zones.

Polythermal is also ideal where the need to reduce air leakage is important. The foam seals the cavity, does not shrink or allow air to pass through it, therefore air leakage through the cavity can be reduced to zero.

Polythermal stabilises the wall by adhering to the inner surfaces of the cavity and providing a continuous structural connection between the two leaves. Because of the greater thermal performance and the reduced air leakage, Polythermal outperforms all other forms of cavity fill. It is hypo allergenic and so contains no fibres, dust or obnoxious fumes.

Certification:

BBA Certificate No. 11/4816. Polythermal has undergone various performance tests. Certificates are available on request.

Technical data

- Specification

- BS 7456: 1991 injected Polythermal into masonry cavity wall

- NBS clause:

- F30, 10 and 150 P11, 50, 220, 230 and 24

- Average depth:

- 75mm

- U-value:

- 0.27W/m²K

- Condensation Risk:

- Zero

- Ventilation:

- Not applicable

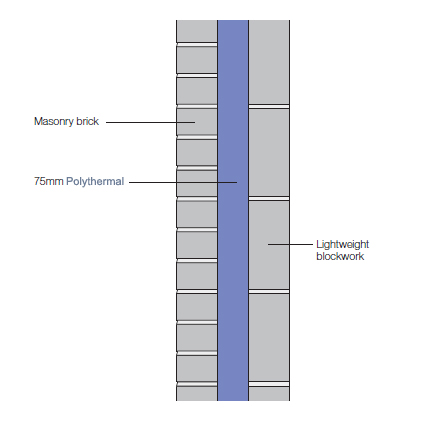

U-value calculation

- Construction details Thickness (solid masonry wall)

- (mm)

- Masonry bricks

- 100

- Polythermal

- 75

- Lightweight blockwork

- 100

- U-value

- 0.27 W/m2K