What Goes Wrong with Basement Waterproofing?

And what we can do to stop it?

May 2025 Newsletter

UNDER PRESSURE: The Basement Waterproofing Breakdown

Basement waterproofing is a critical component of below-ground construction. When it fails, the consequences can be severe—structural damage, mould, and costly remediation. This issue, we’re diving into:

- What commonly goes wrong

- Why these issues happen

- How to prevent them

COMMON ISSUES IN BASEMENT WATERPROOFING

Water Ingress at Joints and Penetrations: Basements are full of vulnerable points—construction joints, movement joints, pipe penetrations, and service entries. These areas are often inadequately detailed or sealed, allowing water to bypass the primary waterproofing barrier. This can lead to flooding during or after construction or minor seepage which can lead to significant internal damage.

Service entries: These are one of the most common causes of leaks and even flooding during and after construction.

Membrane Failures: Tears, punctures, or incomplete coverage of waterproofing membranes.

Hydrostatic Pressure Breaches: When groundwater levels rise, hydrostatic pressure can force water through the smallest defects. If the structure and waterproofing system isn’t designed to withstand this pressure—or if drainage is inadequate—leaks are inevitable.

Condensation and Damp: Poor ventilation or thermal bridging can lead to internal moisture issues.

Drainage System Failures: Blocked or poorly designed perimeter drains and sump pumps.

ROOT CAUSES: WHY THESE ISSUES HAPPEN

Understanding the root causes of basement waterproofing failures is essential for preventing them. These issues often stem from a combination of technical oversights, poor communication, and rushed execution.

Site Investigation: Whatever the site conditions are, water logging must be assumed and waterproofing must be continuous from DPC down.

Poor Design Coordination: Lack of integration between architectural, structural, and MEP designs. A waterproofing specialist must be appointed at the beginning of the design process RIBA 3.

Incorrect System Selection: Using the wrong combination of waterproofing systems and not including a drained cavity (Type C) where necessary to provide repairability.

Substandard Installation: Untrained labour, rushed timelines, or lack of supervision during membrane application. The specialist waterproofing contractor must have a fully recorded quality control system and fully employed qualified staff.

Changing in site management by PC: Changing site management during construction often happens. This leads to problems with sequencing and quality control if the new site management are not fully briefed on the requirements of the waterproofing specialists.

Lack of Inspection & Testing:Waterproofing is often buried before defects are detected. The specialist contractor must provide testing and sign off. Type C should be commissioned and have a full service after finishes are installed before handing over with guarantees.

PREVENTION STRATEGIES: GETTING IT RIGHT

Preventing basement waterproofing failures requires a proactive, multidisciplinary approach. Here’s how to build resilience into your projects from the ground up:

Start Early: Waterproofing should never be an afterthought. Engage a suitable qualified Waterproofing Design Specialist during the concept and design stages to ensure compatibility with structural and architectural elements. Early coordination helps avoid costly redesigns and ensures that critical details—like service entry points and drainage paths—are properly addressed. It is also a requirement of BS8102 and therefore the Building Safety act 2022 which is a statutory requirement.

Assess and document Risk: Carry out a waterproofing risk assessment with the waterproofing specialist as required by the British Standards.

Choose the Right System: The waterproofing design specialist will match the waterproofing type (A, B, or C) to the site conditions and building use.The specialist must consider Buildability, continuity.

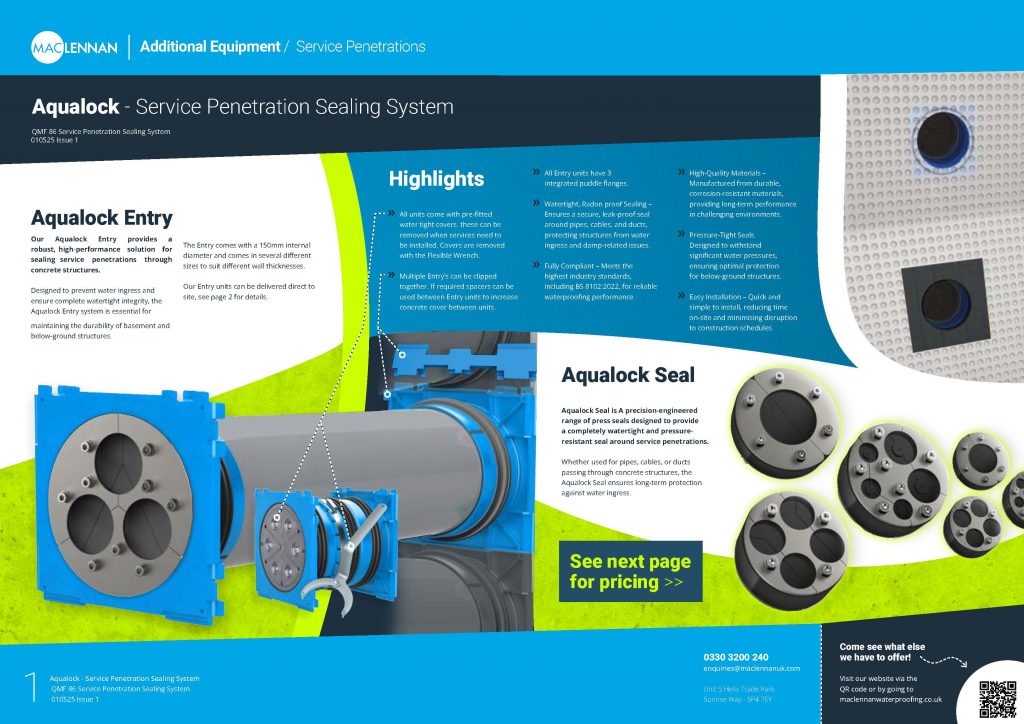

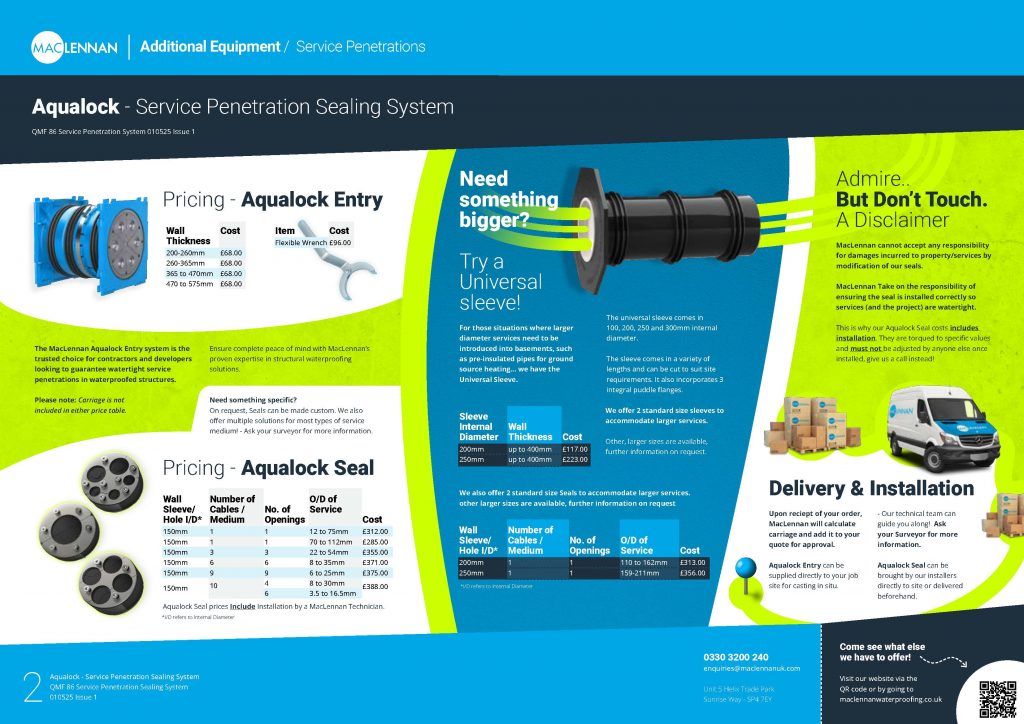

Detail with Precision: The waterproofing design specialist will ensure special attention to joints, corners, and penetrations. Use pre-formed components such as the MacLennan Aqualock system for service penetrations where possible.

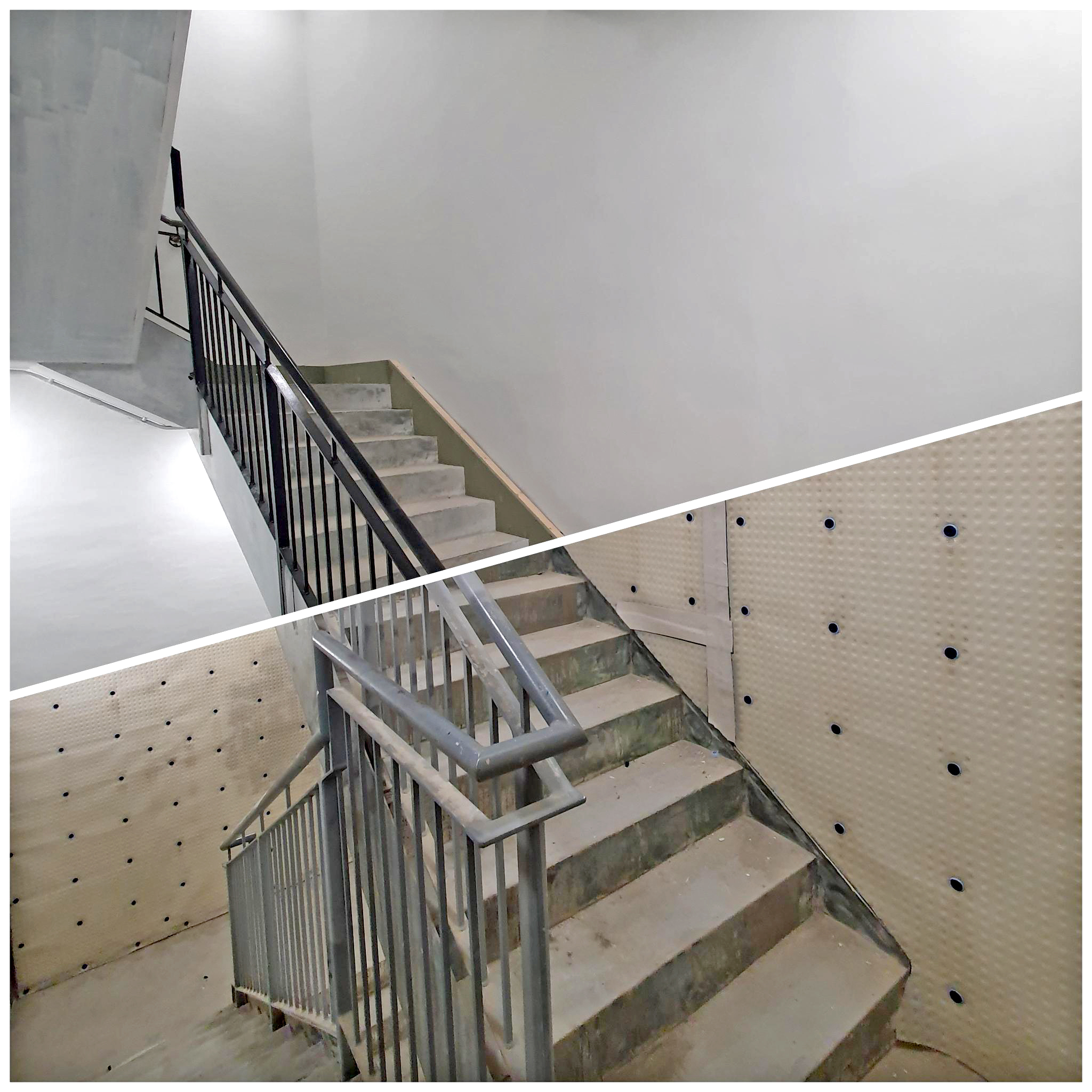

Repairability: The waterproofing specialist must advise the design team on repairability. It is a requirement of the BS8102/22 That repairability after finishes have been installed has been addressed at technical design stages.

Service entries: Must be in the initial design and installed during the concrete placement so as they are gas and watertight. For this we advise Use pre-formed components such as MacLennan Aqualock system for pre formed water and gas tight service entries.

Detail with Precision: The waterproofing design specialist will ensure special attention to joints, corners, and penetrations. All details must be in 3D as required by BS8102.

Ensure Skilled Installation and Supervision: Ensure installers are qualified, experienced fully employed and working under CSSW supervision.

Quality Control: Ensure that work is regularly inspected, photographed recorded, tested, and commissioned and all documentation stored and available if required.

Test Installation: Test decks and external Type A Before You Backfill or cover with finishes. Use flood testing, spark testing to verify integrity. Don’t cover the waterproofing until the system has been signed off. To comply with standards requirement for repairability occupied basements or any basement where the structure is inaccessible due to lining walls, dry lining or finishes will need to have a type C system to facilitate repairability. Link: Why Cavity Drain?

Plan for Maintenance: Especially for Type C systems, ongoing maintenance is essential. Design with:

- Accessible inspection ports which allow camera access.

- Calculate pump requirements for duty pumps and always have a redundant back up pump.

- Alarm systems for pump failure with remote monitoring by installing contractor.

- Installing contractor to provide servicing of pumps and channel carried out by fully qualified service engineers.

FINAL THOUGHT

Basement waterproofing isn’t just a technical detail—it’s a long-term investment in the durability and safety of your structure. By understanding the common pitfalls and how to avoid them, construction professionals can deliver projects that stand the test of time.

MacLennan takes the risk out of waterproofing.