Case Study / Waterproofing

WW2 Woodland Bunker, Dorset

Preserving Historical Integrity While Ensuring Modern Comfort

This case study outlines the comprehensive waterproofing project undertaken to convert a WWII bunker in Ringstead, Dorset, into a modern holiday home.

The bunker, with its historical significance and unique structural characteristics, necessitated a specialised approach to ensure effective waterproofing while preserving its historical integrity.

The WWII bunker in Ringstead is a notable historical structure, originally built to withstand extreme conditions. Its robust construction presented both opportunities and challenges for conversion.

The goal was to maintain the bunker’s historical essence while transforming it into a comfortable and habitable space.

The project was managed by the same client who successfully oversaw the Pitt Bunker project the previous year. Leveraging their experience and expertise, the client ensured that the project adhered to both modern building standards and historical preservation requirements. See the other bunker project here

Method

The project involved three primary elements of work:

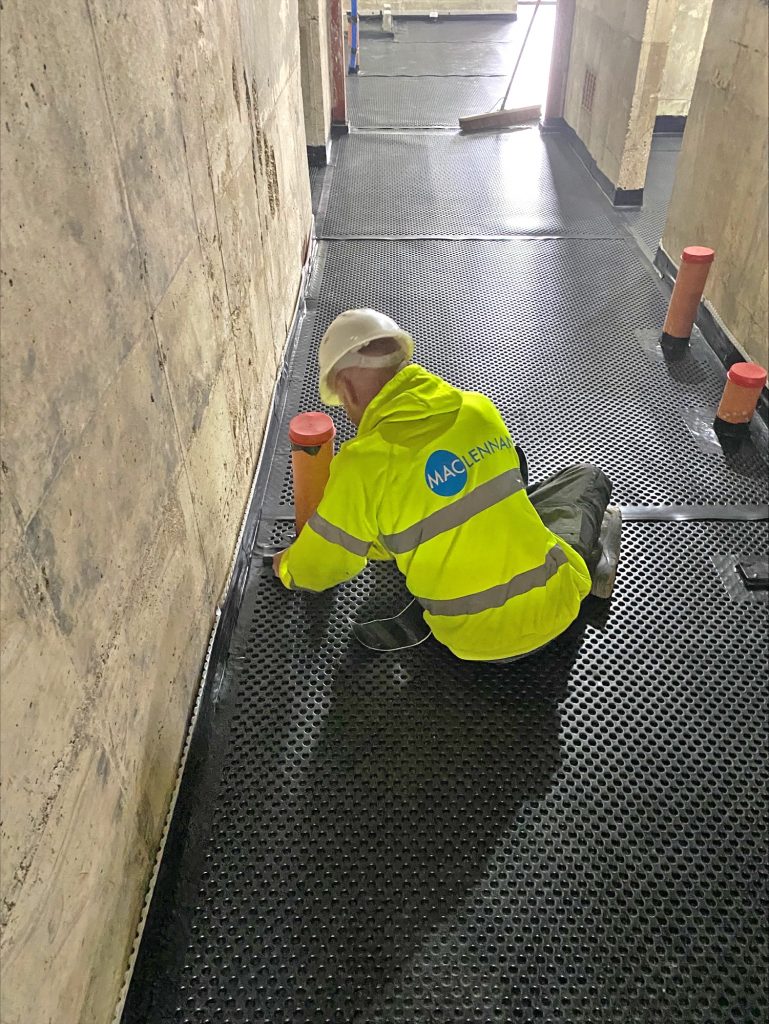

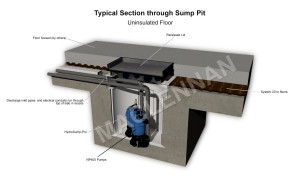

1. Internal Waterproofing: Cavity Drain System: To preserve the WW2 bunker aesthetic and avoid covering the exposed concrete walls and soffit, a fully serviceable and maintainable cavity drain system was installed up to the finished floor level, as requested by the client. This system included a condensation strip to manage any water entering at the kicker joint, directing it into the drainage system. The System-08 ventilated cavity membrane was supplied and fixed around the perimeter to the top of the floor finishes. Additionally, a Hydrodrain channel was installed around the wall-floor join, and the System-08 ventilated cavity membrane was applied over the floor areas.

Challenges and Solutions: The historical nature of the bunker meant that traditional waterproofing methods could not be applied to the walls and soffit. The team had to innovate by focusing on the floor, ensuring that any water ingress at the kicker joint was effectively managed. This required precise planning and execution to maintain the structural integrity and historical value of the bunker.

2. External Waterproofing: Sprayed Foam Insulation and Polyprufe Liquid Membrane: The external walls and terrace were treated with sprayed foam insulation followed by the application of PolyM liquid membrane, ensuring comprehensive external waterproofing as well as providing additional insulation from outside.

Challenges and Solutions: The external waterproofing had to be meticulously applied to ensure no water ingress while preserving the bunker’s exterior appearance. The use of sprayed foam insulation and PolyM liquid membrane provided a seamless and effective barrier against moisture, showcasing the team's technical expertise and attention to detail.

3. Blast Wall Treatment: Hydrogel system: The main entrance features a newly constructed wall, designed to resemble a bombed structure, known as the 'blast wall.' This wall was treated with a Hydrogel system, an invisible product that provides protection to both the steel reinforcements and the concrete by reacting with any penetrating water to form a gel that prolongs the life of the concrete and stops the metal corroding. This treatment ensures the wall maintains its "blown-up" aesthetic while being structurally sound.

Challenges and Solutions: Preserving the appearance of the blast wall while ensuring its structural integrity was a significant challenge. The application of the Hydrogel system allowed the team to protect the wall without altering its appearance, demonstrating a balance between historical preservation and modern waterproofing techniques. It waterproofs the concrete and protects the re bar while not changing the look of the concrete. This is an innovative system that MacLennan are introducing into the UK waterproofing market.

Additional measures included:

Gravity Drainage: An external applied waterproofing system with a maintainable land drain system was recommended.

Floor Inspection Ports: Floor-mounted inspection ports were installed to comply with BS8102 and manufacturer recommendations, this was in place of the standard wall mounted inspection ports. With being floor mounted, they could be hidden from view with access panels placed on top.

Lime Inhibitor Application: A lime inhibitor was sprayed over the floor areas with upstand to protect the system from lime.

InsuFloor Installation: InsuFloor Grooved 50mm thick floor insulation was laid onto the structural floor slab before the floor membrane was applied.

Results

MacLennan successfully addressed the unique challenges posed by the WWII bunker conversion. The internal cavity drain system effectively managed potential water ingress, while the external waterproofing and blast wall treatment ensured comprehensive protection.

The collaboration with architects and adherence to industry standards resulted in a robust and reliable waterproofing solution.

We provided our own design and were engaged to carry out the installation, offering a comprehensive design, supply, and install service.

As part of this service, we assume full liability for the waterproofing design, which is covered by our Design Guarantee and protected by our £10 million PI insurance.